Summary

- System architecture

- Heuristic-based interpretation and inference

- Sensor model

- Probabilistic Inference over RFID Streams

in Mobile Environments

- RFID supply chain simulator

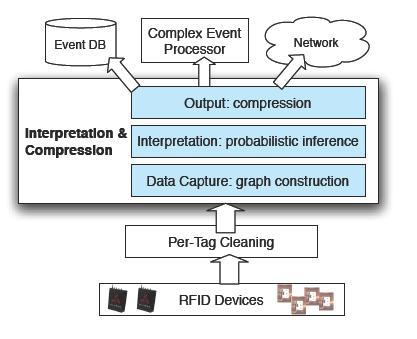

The SPIRE system employs a data interpretation and compression substrate. The substrate, epicted in Fig.1, consists of the following three modules:

- data capture

module that implements a stream-driven construction of a time-varying

graph model to encode possible object locations and containments.

- Interpretation

module that employs a probabilistic algorithm to estimate the most

likely location and containment for an object.

- Compression module that outputs stream data in an compressed format.

Figure 1 Architechure of SPIRE system

Heuristic-based interpretation and inference

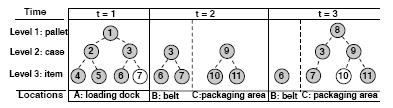

Time-varying

colored graph model G=(V,E)

encodes the current view of the objects in the physical world,

including their reported locations and (unreported) possible

containment relationships. In addition, the model incorporates

statistical history about co-occurrences between objects.

The node

set V denotes all RFID-tagged objects in the physical world. Our graph

is arranged into layers, with one layer for each packaging level. Each

node has a color that denotes its location.

The directed edge set E encodes possible containment relationships

between objects.To enable

probabilistic analysis, the

graph also encodes rich statistics. Each edge maintains a bit-vector recent co-locations to

record recent positive and negative evidence for the co-location of the

two objects. Figure 2 is an example.

Figure 2 An example of Time-varying colored graph

Given that the read rate of an RFID reader is less than 100%, it is natural to model the reader's sensing region in a probabilistic manner: each point in the sensing region has a non-zero probability that represents the likelihood of an object being read at that location. To determine the probabilistic values for different points, we can represent the sensing region as the likelihood of reading a tag based on the factors including the distance and angle to the reader.

Probabilistic Inference over RFID Streams in Mobile Environments

The

task of data cleaning and transformation is essentially to recover the

facts necessary for query processing while mitigating the effects of

data loss and sensing noise. Toward this goal, we employ a principled

probabilistic approach to (1) model precisely how mobile RFID data is

generated from those facts about the physical world and (2) infer

likely estimates of the facts as noisy, raw data streams arrive.

Modeling

the data generation process. First, we design a probabilistic model

that captures the underlying data generation process, including the key

components such as reader motion, object dynamics, and noisy sensing of

these objects by the reader. In particular, our model employs a

flexible parametric RFID sensor model that can be automatically and

accurately configured for a variety of environments using a standard

learning technique.

Efficient, scalable inference. To generate

clean location event streams from noisy, raw RFID data streams, we

apply a sampling-based inference technique, called particle filtering,

to the probability distribution developed above. To enhance particle

filtering to scale to large numbers of objects and keep up with

high-volume

streams, we develop advanced techniques, namely,

particle factorization, spatial indexing, and belief compression. These

techniques lead to a solution that uses only a small number of samples

at any instant by focusing on a subset of the objects, while

maintaining high inference accuracy.

In order to design a distributed system for tracking and querying massive amounts of RFID tag data in a supply chain scenario, it is first necessary to create large data sets of sample data that can be used for testing during the design process. The purpose of RFID tag supply chain simulator is to create sample output files that will simulate the reads that a large set of products would create during their route through a retail supply chain.

This simulator is written in C++ and requires the use of the csim software library by Mesquite Software. It also uses TinyXML, an open source XML parser, in order to implement an xml configuration file that dynamically defines the supply chain at runtime. Information about the EPC tag data standards can be viewed in the standards document on the EPC Global website.

Architecture

Figure 3 Use Case Diagram

Figure

3 describes interaction between external entities which locates outside

of the system boundary. Two actors will interact with this simulator,they

are Tester and RFID Middleware. Tester will run the simulator to

generate trace file and RFID middleware use these file to work on RFID

stream data. This Use Cases of RFID supply chain simulator include: Run

simulator, Parse configuration file, Generate object, Move object, Run

reading process, Generate trace files. Figure 4 shows the module view

of overall architecture of this simulator.

Figure 4 Module View